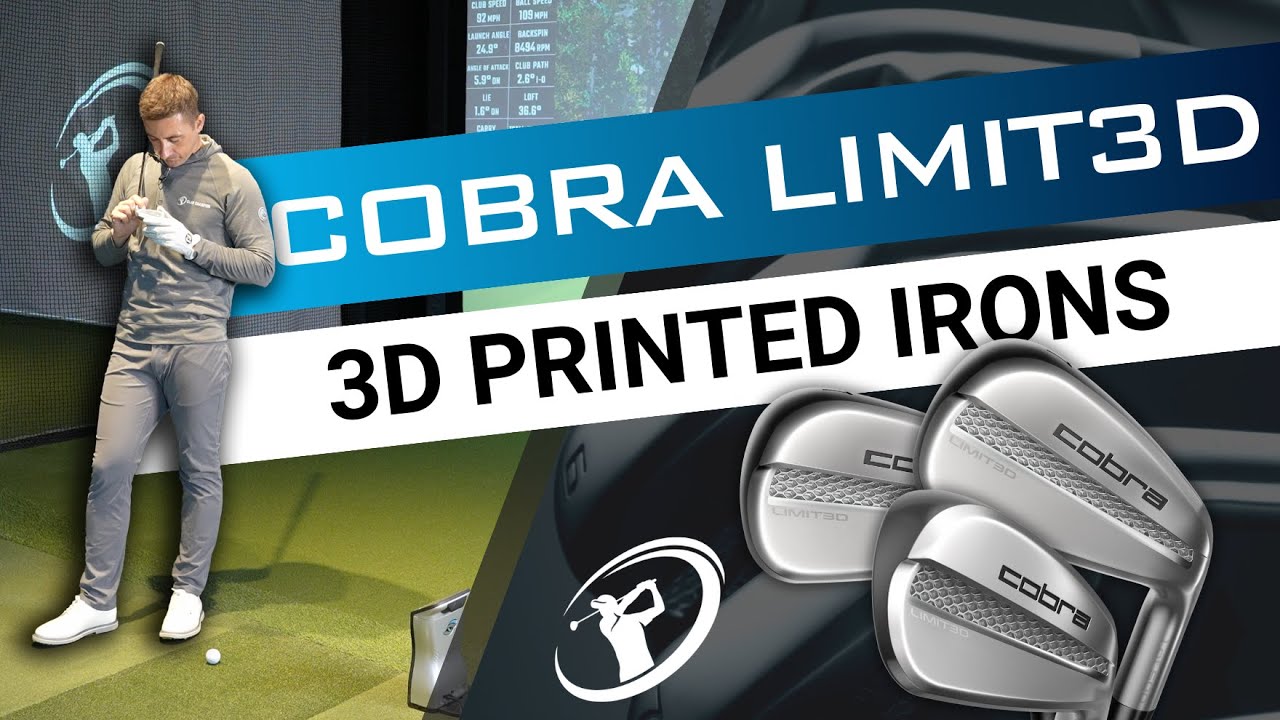

Today, Ian is in the bay to review one of the biggest advancements in golf club technology. The COBRA LIMIT3D irons which are the world’s first 3D-printed steel irons.

Their one of a kind design, features a forgiving blade shape with the sleek look and soft feel that better players desire. Only

500 sets of LIMIT3D irons will be available for sale globally.

BOOK A FITTING

CANADA: https://bit.ly/41mBbmg

USA: https://bit.ly/3TtgSli

SUBSCRIBE TO THE CHANNEL

https://bit.ly/3TrDLVX

FOLLOW US ON INSTAGRAM

Club Champion: https://bit.ly/48iAyMH

Ian Fraser: https://bit.ly/48jglq1

Mike Martysiewicz: https://bit.ly/48hejGR

https://bit.ly/41mBbmg

Filmed at: Club Champion Toronto

Custom Golf Club Fitting Studio – Toronto, Canada

that’s a good one because I didn’t hit it very well right caught it very thin Got Away With It 15 mm low yeah all right guys welcome back to the channel so big review today Michael exciting very exciting Cobra limited irons 3D printed we’re in the future baby we’re in the future this is a look into the future um there’s a quite a lot of Buzz there has been certainly uh about 3D printing and and how that’s going to influence the future of golf clubs we are seeing it here this is the first set to come to the mass Market um Bryson obviously has been dabbling a little bit in his own world with uh with 3D printed golf clubs but Cobra really in all honesty and I’ve been a little bit privy to to some of the conversations around this 3D stuff for a while it was probably two years ago you know we we done all the kind of you know non-disclosure agreements and all that stuff and we actually had a conversation with Cobra about uh 3D printed irons and what that future may look like and we we got a little look behind the curtain as to some of the things that they were doing so wasn’t surprised to see this come but um very impressed with the first the first sort of uh product that they’ve put out there it feels quick that they’ve come to like technically Mass market right you can eventually buy these uh sets of irons but um you know if we’re here now what’s 3D printed look like in 10 years time are we printing irons to a person um not in 10 years time yeah who knows before that before that who knows but it’s impressive yeah I think I think you’ve you’ve basically hit the nail on the head of the future of what 3D printing offers it’s the individualization of these types of products it’s the ability for these to be made in smaller batches it’s good it’s costly for now that’ll go down as as uh you know machinery and parts and and sort of processes are are sort of they can speed that up a l little bit but as of right now it’s quite expensive yeah for sure which is fine I mean there there’s other you know very popular golf clubs in the golf industry that sell often every day for the same price the Murs of the world yeah you know obviously title concept you know there’s there’s lots of other irons that are selling at this price point so I I don’t I don’t look at the the prices to be honest as a detraction it’s not like they’ve went at it double what that was right cool yeah so we’re going to test some four iron seven iron pitching wedge thoughts right out of the gates when we I mean we took them out of the box we’ve all looked at them I mean right away for me very clean very um not blady but like definitely there’s some help behind there but really really impressive looking really impressive uh very very much a muscleback look it’s simple I mean I I love when a manufacturer just leaves this sort of this pad fairly blank just puts their name on it like you know we’ve seen other companies do that and I love when they do that it it just it’s very very simple there’s no there’s no kind of like flashy highlighter of colors on there there’s there’s none of that it doesn’t need it no because all the all the important stuff is under the hood you get a little look at it with this lce design at the back um an idea of of obviously how they’re able to save the weight that they are in order to put the amount of tungsten they have in in the toe and the heel an amazing feet in itself something that really is is kind of been desirable for a long time but not not possible definitely I mean that’s not just aesthetic you know the the inside we’ve got some images I’m sure we’ll put in this video there’s a lot more of this inside it’s it’s cool that they’ve exposed it because I think it you know definitely shows people like yeah this is this is what we’re working with but um it looks awesome excited to see the numbers without a doubt all right let’s get into uh let’s get into some numbers um we’re looking at these being quite like King tour um one degree stronger in in Loft though so um you know they’re not they’re not players they maybe are borderline players distance in in performance they certainly aren’t in looks right so uh yeah let’s let’s see what they what they give us if 140 yards a little longer than what we normally have the green set to just a loft thing yeah I mean I think probably 136 to 140 is probably going to be the carry number mhm yeah Loft uh I play my own pitch wed at 45 this is this is kind of you know similar to that I just I hit a few with them they feel like they’ve got I don’t know whether it’s the the stability you get from the tungsten and just feeling like every shot’s a solid shot but I just feel like they’re going to go going to go pretty far okay let’s see it solid strike out of the G yeah pretty good little lower strike they actually don’t they don’t feel like they’re there they feel they feel not bad at all better yeah nice strike better Michael I mean right now those three strikes basically 10 mm low yeah again with the help of that tungsten you you really do get away with it spins really good launches nice so uh so pretty manageable isn’t it m high in the blade pretty consistent he F into the seven iron um I see you looking at that lattice 3D printed I like I said earlier um the whole head is like that on the inside and then down below we have up to 100 gr of tungsten yeah not the heaviest we’ve seen in the industry but obviously the trend we’ve seen of you know tungsten low we saw it on the wedge you’re you know quad was saying you’re 10 millim 11 millim low on the head and I mean you would never no think that now without tungsten I’d love to see where those shots were and how that spin changes yes that’s the thing isn’t it it’s the this the you know unstable nature of that that spin the the ball speed sort of dips all those sorts of things like it feels to me it’s like it’s like riding a bike with with kind of like training wheels on or like putting down the stabilizers on a cruise ship like you know putting that mount weight out out wide yeah just stabilizes the whole Mass doesn’t really matter what it gets hit with it’s going to be much more stable than if it’s in its narrow CG you know kind of obviously CG position still there Ry but you know when you place Mass out on this side it really makes the are so much more stable um so yeah we’ll see a little bit about that you know obviously I’m very likely to test it I think with all that tungsten too it gives you the or just giving someone a stable iron once you get fitted gives the customer who maybe would like something Slimmer looking yeah that’s who this is aim that isn’t it but also the the Forgiveness that they probably should use in in other irons that’s I mean it’s a nice thing you can get into an iron that maybe looks a lot more appealing to the eye and it’s got a ton of forgiveness to it you’ve got Forge Tech and Forge Tech X this is more forgiven than both of those big profiles yeah so maybe you just you’re put off by that you know that sort of look but obviously the the inflated size and footprint of that head is to try and sort of spread the mass well if you can get sort of the ability to maneuver the materials how you want it save the weight that you want then you’re going to give people the look that obviously they they desire but the performance that they need all right let’s let’s see what Seven’s got now under the locker or in the locker Michael that’s a good one because I didn’t hit it very well right I caught it very thin Got Away With It 15 mm low yeah better Mikey a nice flight mhm sounds great does sound good doesn’t it yeah I think that’s going to be a concern for some people as a 3D printed part in some way inferior or um less robust than than a sort of you know forged yeah pressed part something that’s been you know pressed the way we see the Japanese forged clubs Muno Forge clubs but when I saw the finished part I was really really really impressed we’ve been sort of sent 3D Parts before of of new models to look look at and you see it’s it’s kind of normally unpolished it’s it’s got that very raw look to it when I saw these for the first time I couldn’t I couldn’t quite believe how you really would never know this is a 3D printed part you’d have no idea no and when we you know when we hit it when we first got it you know the original media sample of seven iron we all H and we’re like yeah I mean it’s very hard now to feel the difference between forgings and and CID clubs cuz the products are so good but this is yeah for 3D printed you would never you would never think it’s you know multimaterial no not a chance all right F into the four iron thoughts on the looks of the forearm does it get a little longer heel the toe or stays pretty compact very compact it it just like you become aware very aware in the forand of how little offset is on these irons so that’s of a little less offset than the king tours uh when looking at the spec sheet so this is though where you start to be more aware of having the the help yeah you know we have we see obviously how many players play combo sets nowadays and I think the nature of the the freedom in design that 3D print gives you what I think we’ll see in the evolution of the placement of weight and how much we put a for iron versus a wedge and you can truly make an individualized set of irons based on the amount of Freedom you’ve got in the design definitely think that that weight savings from the the the non sort solid structure of the inside of the head is is going to really make the set a a kind of whole new ball game it’s going to be a brand new sort of almost people have to rethink the thing you know like from the start it’s like wipe the slight clean let’s let’s start thinking of this again but let’s let’s see very good your toy mhm was solid Mikey I like that flight yeah it’s powerful isn’t it a good looking flight I was worried as you get to the 6 five4 iron with that lattice structure in the back that it would get you’d get that really high pitch kind of clicky sound I don’t think you get that at all no sounds really solid all the way through it it really does that sounded so good all right L it thought yeah I’m I’m impressed I love the sound of them like we talked about uh it’s it’s not a forged iron the 3D printed iron with a you know different kind of way they’re making this material they sound great I mean and you said they feel fantastic which you know I hit these earlier and I I do like the feel of them as well impressive iron cool to see 3D printed irons coming to Market very limited with uh with this set I think 500 sets Global um you know $3,000 um but yeah cool I think I think they they performed really well gorgeous gorgeous set of irons uh to look at really nice to hit I will say that I feel like like performance wise they’re in line with what I see other irons that look like that do so it’s not for me the performance is not what has blown me away here it’s the opportunity and the future of what they’re capable of from uh 3D printing that is is really got me excited after this test um yeah I think the the irons felt felt really nice kind of in keeping with the the t150 type thing the Muno 243 type irons that’s the type of iron but obviously it’s got more forgiveness you know we talking about close to Triple the amount of tungsten being used and again guys we whether it’s whether it’s the other channels you guys pay attention to you’ll hear everyone harping on about the amount of tungsten but it’s just it’s been able to use more meaningful material in the head in order to sort of mask those M hits um the last few four irons I hit were the best the best strikes I hit yeah uh in the whole test and my goodness it felt good yeah it really really did Club speed’s quick off it uh ball speed is really really good um again all your standard deviations and spin were really really tight like it’s yeah impressive that’s good for a four iron isn’t it impressive set IRS I think the cool thing is we were looking at a a deck earlier of that Cobra sent us and they talked about Moi and forgiveness in an iron I mean we talk about that in woods all all year all year long oh the most Moi most forgiveness you know you talk about in Putters now but to to really have it in the conversation with these irons is it’s different it’s cool it’s it’s an addition to the industry that you know I think everyone’s going to start going towards that going to change things isn’t it and that that was that was my initial thought was this seems like a bit of a a shift uh in in Iron design and something that will be meaningful moving forward there are kind of sort of time stamps of when heads and shafts became interchangeable when movable weights became you know part of the the whole gig uh material started changing with carbon being added in there this sort of feels like one of one of those it initially comes at a high cost and then obviously the the sourcing of the materials and the processes you know gets a little bit more cost effective and that cost saving gets passed on to the consum and you guys benefit down the road from that so yeah impressive stuff uh from Cobra I just can’t see what they’re going next I I knew this arm was coming two years ago um so the nature of these things is what they actually have what they’re looking at right now with this yeah is what excites me you know this is probably being concept since that two years and you know that two years ago sort of timeline what they are must be doing with that in in uh in Prototype right now will be fascinating yeah it’ be night and day difference I mean probably from a year’s time you’ll maybe we’ll see more for them I saw photos of some of their 3D printed Putters um yeah you know cool to see them put into Woods in the future but yeah excited to see what comes next definitely definitely all right well congrats to the guys at Cobra amazing breakthrough uh in the industry amazing for them to lead the way in this new sort of uh manufacturing process of 3D printing golf clubs and changing the game I think the game has changed it really has you know and it’ll be interesting to see who follows suit um but to be first to it you know kuros to to Cobra Golf 100% excellent all right guys uh lots more to come from us much more testing there’s there’s a few more few more clubs coming through the door in the summer season a few uh few new additions to The Matrix coming in Michael yeah for sure lots more to to come so stay tuned for more and we’ll see you again soon [Music]

23 Comments

i was tempted to buy a set but alas my ass don’t wake up in time to purchase them at 530am. c’mon Cobra. that’s some cold shit right there. how about 10am

I'm curious about the potential benefits of 3D printing an iron. While it currently seems like a gimmick, this technology could offer significant advantages in the future. I just can’t see what it is now.

Can't wait to see a real consumer offering. Been designing 3D model golf clubs as a learning tool in CAD for years now.

With them exposing some of the lattice structure, is there not a concern of water/dirt/mud getting into the club head?

Ordered a set. Excited to get them.

LFG! Stoked for these

As somebody with an inside connection with Cobra R&D I know what the future of these are and it's absolutely exciting. I am SO proud/excited/thrilled for the Cobra dev team that these seem pretty universally well received. It would be easy enough for cynics to dismiss this as a gimmick if they didn't perform well/feel well/etc but it's so great that through all the tech focus they ultimately are a great performing iron and do what they say they do.

Anybody want to venmo me 3 grand? lol

I tried to buy a set 30 minutes after release and they were sold out

Giw did they get the powder out of the inside of these is my question. That's as much a feat as just making the clubs

Hearing Yags talk about the possibilities is exciting. These are a great start.

Why is the cost so much higher, because they can ,or it cost Cobra more to produce?? Golf equipment is way out of line already, but ill say Cobras been pretty fair with pricing thru out the years, just an example, the Ping G430 10K $ 699 as a standard buy off the rack, come on Golf companies get a grip, so unfair to the customer. upgraded shaft were looking over a thousand for 1 club, not cool , shame on the greed.

Congratulations to Cobra for being the 1st to mass market. Unfortunately this will force the big three to step up and do it better, faster, cheaper leaving Cobra to be a footnote in history.

This is the future and it starts with a very pretty players distance type iron (as Ian said right on the border between players distance and normal players iron). For me this is a competitor to the i530, P770 and maybe Mizuno 243 or 245 and similar.

I love the fact that Cobra have finally listened to buyers and stopped using the back of the club as a cluttered advertising billboard for all the tech brand names.

IMO there will always be a place for forged clubs probably players small cavity back irons will always be forged but I can see over the longer term 3d printing developing in 2 ways. There will be mass marketed 3d irons that within 5 years will be cheaper to produce that traditional forged or cast irons. But there will also be a premium market, where every iron is personalised for the particular customer not just on loft lies but also sole width, placing of tungsten etc. – could make fitting an even longer and more involved process than currently!

Kudos to Cobra for this development, that is real innovation – and not for the first time from Cobra – rather than, as so often happens, manufacturers simply recycling old ideas with incremental improvements

Is the weight lower with the 3d head compared to a similar standard technology head that provides the same forgiveness performance

Imagine the future where a fitter could order a set literally built for your swing. Everything about them could be changed for a fraction of the cost of a traditional club. In 10-15 years every golfer could have a bespoke set.

Can you do a iron comparison of the cobra 3d model to a titleist iron model

You guys seemed underwhelmed by these irons lol

How is the 3D printing in regards to adjusting lofts and lies? Like forged? or like cast?

I think what I am impressed by is the consitency it gives. Less than 200 standard deviation in spin across that span of clubs is impressive. 2 yards of standard deviation on carry, and the 4 iron landed in the same spot each time which I think is pretty rare on the longer irons.

The hope here is that 3D printing can bring the cost down in the long run. Lower cost = more clubs in hands

Do they print the tungsten into the iron as well? Or is the shell printed, tungsten placed and then the shell gets laser welded together? I see a cool custom future on the horizon. Get your check book ready.

95 mph 7 iron, someone’s been in the gym.

These look stunning. Might be a pain to clean any mud out of the back lattice, but stunning nonetheless!