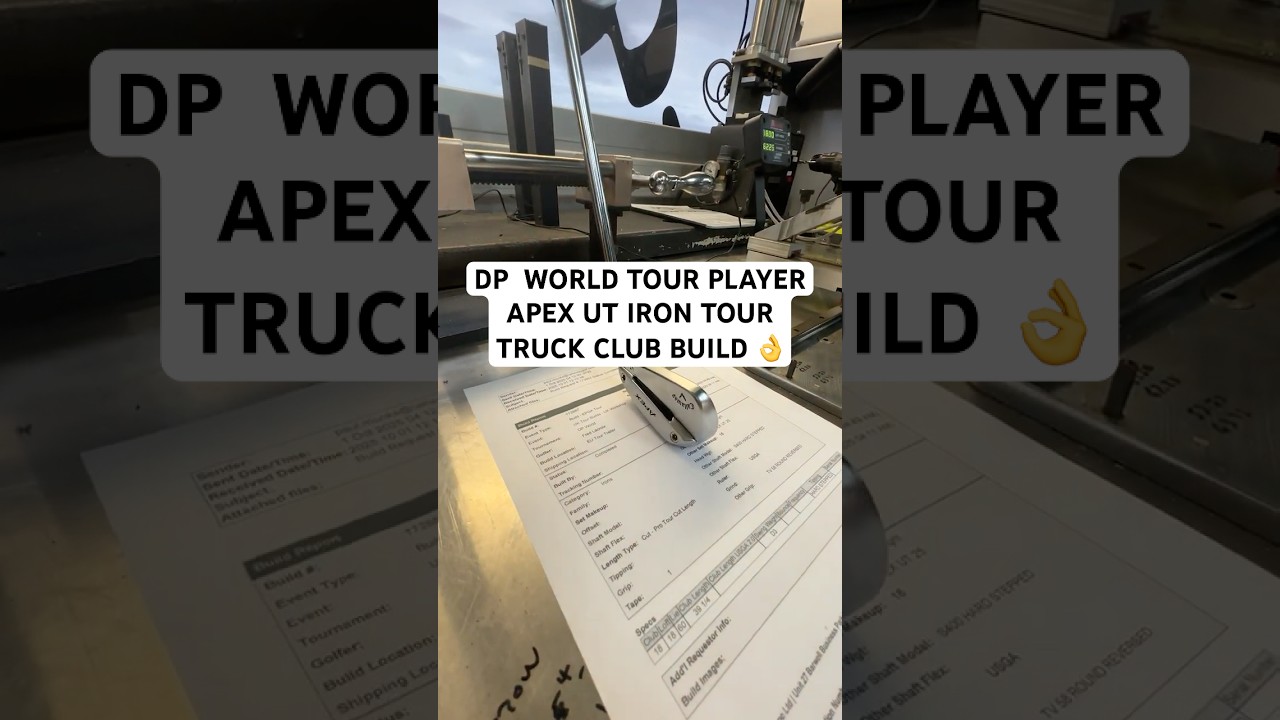

From the tour truck to the tee – watch Fred Lacroix’s NEW Apex UT get built to perfection by our Tour Team.

👉 If you could get our Tour Team to dial in one club for you, which would it be?

So obviously we’re at the Dunill Championship this week, so we’re getting a lot of requests for driving irons. The boys have been on the range to fit Fred Laquire and we’re going to build him a new Apex UT 18° driving iron. Quite unusual this one with Fred cuz he uses S400s, but he we’re going to put the four iron shaft in the two iron. He just feels that that just gives him a bit more stability and it’s kind of the flexes in between S400 and X100. We prep the tip so the tip will bond into the head when we use the glue. Double check the loft and lie just from a dry build point of view so we get the length right. Cuz what we do on here, the way we build Cubs on tour is we preset all the lies and then we cut to the lengths. So cuz if you change the lie by a couple of degrees, then you’re going to change the length. So if you went more upright, you’d make the club shorter. If you bend the club flatter, it would measure fractionally longer. We like to um overcut fractionally. Perfect. I would grip the shaft. So then everything’s dialed in to the shafts and which will be a key point for the end total when we’re trying to match the swing weight up. Fred has his grips reversed. So what I’ve done is I’ve married up the screen print up. So now I can just put logo up, but when I build it, we’ll do logo down. So now we’re just dial in the swing weight. So, we just use 3 g tip plug. Tiny bit of aluminium oxide. As opposed to glass bead, we just find that the aluminium oxide doesn’t crush or creek. Helps center the shaft. Spiral the glue. Square the grip up and then we’ll just put it there to dry. The glue is all set. We’re just going to just trim the fereral. Just polish the fereral up. Double check will often live. So, we want 18 and 60. And that’s it. It’s ready for Fred to hit.