In the world of golf equipment, we often take for granted that the numbers printed on our clubs are accurate. A 9° driver is a 9° driver, right?

Well, as a gear tester who has measured over 30 current in-line drivers from both major manufacturers and smaller DTC brands, I’ve discovered a surprising and, frankly, worrying reality.

You may like

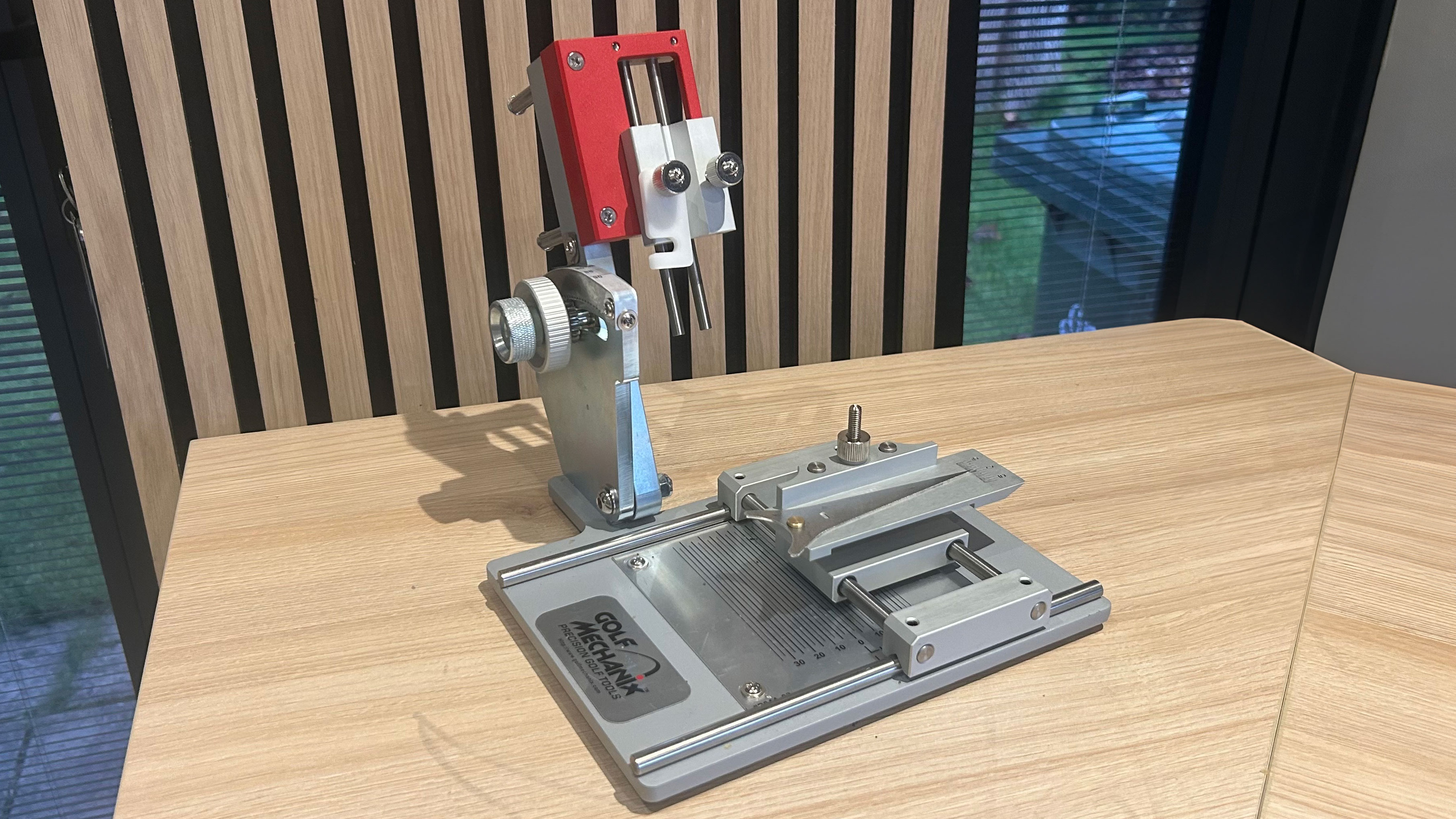

The Golf Mechanix Precision loft and lie measuring gauge

(Image credit: Future)

We’ve known for some time that there are manufacturing tolerances in the golf equipment industry. The facts are, it’s incredibly difficult to produce the best drivers – especially those with multi-material heads that are precisely pieced together to the same specifications. However, the scale of the discrepancy I’ve uncovered is far beyond what I would consider acceptable.

Many of you may not be familiar with the type of gauges used to measure these specs, as they are not as commonplace as the ones you might see in your local pro shop built for irons and wedges, but they are essential items of kit for tour reps on the professional circuits.

(Image credit: Future)

If you have ever watched any behind-the-scenes tour truck-style videos on YouTube, you may have noticed the little white stickers adorning the driver heads that pack out the drawers of the truck.

This signifies that the head has been individually measured for loft, lie, and face angle (among other things) on such a gauge, and the sticker is where the results are recorded so that the tour technicians can cherry-pick the heads with the exact measurements they require for a specific build.

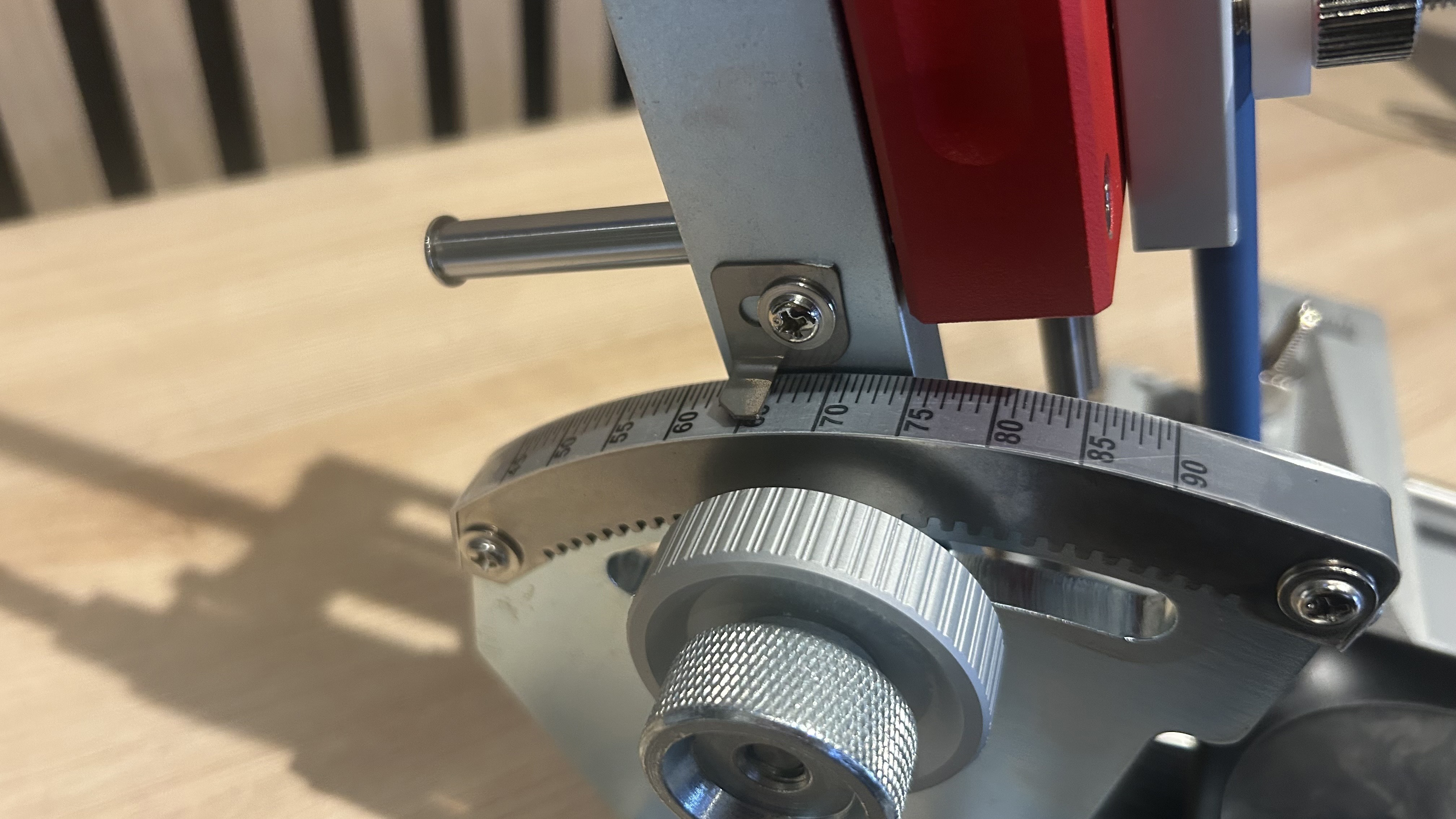

It is imperative to ‘zero out’ the face angle of the driver to get an accurate loft reading

(Image credit: Future)

All the drivers I measured for this exercise came from ten different manufacturers, had a stated loft of either 9° or 9.5°, and were all measured in their standard loft sleeve setting. Looking back on my findings on loft, I was genuinely astounded to see a spectrum of measurements ranging from 7.5° all the way up to nearly 11°.

While trying to make sense of this information, clutching at straws, I wondered whether these worrying differences could be down to individual manufacturers using slightly different measuring methods. So, to test this theory, I ventured to my local pro shop and measured three 9° drivers (one came from the fitting cart) for sale on the shop floor from what would be considered one of the ‘top four’ brands in the golf equipment space.

(Image credit: Future)

The tolerance was tighter than the range I experienced in my workshop at home; however, the three measurements were still 8.25°, 9.1°, and 9.75°.

Now, that might not seem like much of a problem, all within a degree of what the manufacturer states on the clubhead, but consider this circumstance. You have visited the PGA Professional at that shop for a custom fitting and, delighted with the results, you decided to purchase your new driver.

The head you were fitted for was the one that measured 8.25° (which, in this case, was actually the one from the fitting cart), but the head that is ordered and arrives for you turns out to be the third head, measuring 9.75°. That is a difference of 1.5° between what you were fitted for and what you received.

Lie angle is a hugely underrated specification of the driver to get correct

(Image credit: Future)

That discrepancy is going to have a massive knock-on effect in terms of your launch, spin, ball speed and overall distance. In truth, it almost totally negates the custom fitting you just went through.

Furthermore, lie angle doesn’t get away scot-free here either. While you might think that lie angle is irrelevant in a driver because you are not taking a divot (hopefully), it has a massive effect on launch direction.

Most modern drivers specify a lie angle of around 57° in their standard setting, and while a majority of the major manufacturers I tested managed to hit their specified numbers within a degree, it was concerning to see a couple of the DTC models much further away. One, for example, stated 57° on its webpage but came in at a super-upright 60.5°, a full 3.5° away from what was advertised.

These results give further credence to my theory that if you are going for a custom fitting and end up finding a driver or fairway wood that you are happy with, there is a real case to speak with the fitter and let them know that you want that specific head used during said fitting.

While it may be an unusual request, it seems this is about the only way you can guarantee you are getting what you want at the consumer level, and if they want your money, they will likely comply. If you order one in from the manufacturer, based on my findings here, you are somewhat rolling the dice.