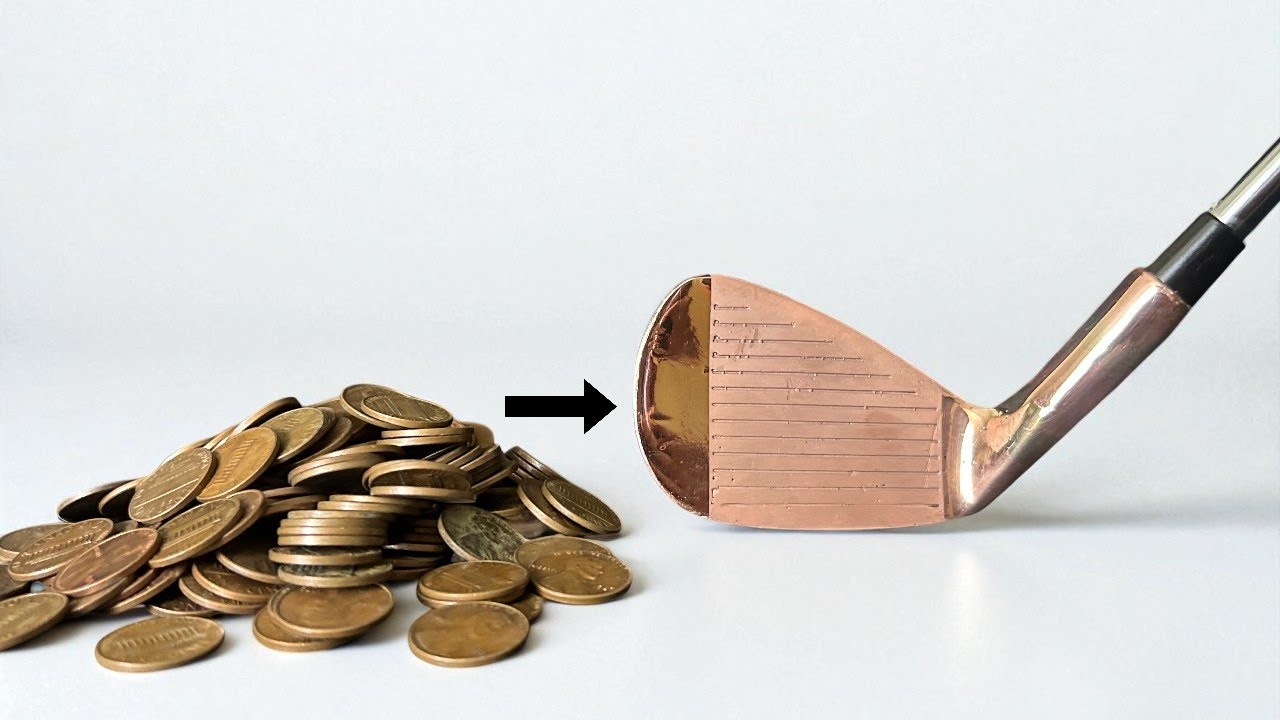

Making a Golf Club Out of Pennies

We’re casting our own eight iron out of pennies, taking it to the range, and testing it on a launch monitor to see how it performs. No one’s really making golf clubs on YouTube, so we’re going to do just that. The goal for this video is to make a fully functional eight iron out of pennies. The process starts by making a wax version of the club. We’re going to use the lost wax method to make this iron. It’s the same technique used in jewelry and actually how golf irons like the Ping I2 were once made. We used a silicone mold of a Mizuno MP68 to shape the wax, added venting, and placed it in a steel flask filled with investment plaster. After baking the mold in a kiln for 14 hours, we melted down a bunch of pre980 pennies, which are 95% copper and 5% zinc, and poured the molten metal into the mold. The casting turned out solid. Relatively clean grooves and no major flaws. And now we just had to clean this thing up and get it glued onto a shaft. We cut off the vents on a band saw, cleaned up those cuts on a grinder, and drilled out the hoszle. Since the casting didn’t go to full depth, we had to do a little bit of groove work with the Dremel just to clean up the bottom groove a bit. After that, we polished it up on the buffing wheel, which is a bit challenging to do if you’ve never tried buffing an iron head on a wheel. Packard’s first try polishing an iron on the wheel and got caught by an edge. bent the huzzle a bit, but really just mostly concerned with the overall strength of this thing as an actual golf globe. We were able to straighten out the huzzle on the drill press, but after doing so, we noticed a crack in the huzzle, which was not going to fly. Here it is side by side. The Mazuno slightly thinner top line. Everything else looks pretty spot-on, but obviously we got to we got to do something about that cracked hoszle. So, we took it to the best welder we know to see if he could do something with it. This is something we were not going to be able to weld. It’s not an easy welding job working on something this small and thin. Luckily, this guy’s really, really good, and he was able to weld on a copper sleeve over the hoszle that will hopefully add a decent amount of strength to the club. Took it back to the shop and had to do a little bit of touchup and redrill the huzzle. Got it repolished, sand blasted the face, and glued it onto a S300 shaft, which is the same shaft the Mazuno 8 iron has. And our club was ready to test. It was quite windy at the range that day, so apologies for the bad audio quality. We’ve got our copper 8 iron uh that we’ve made and we got the hoszle welded up. So, we’ll uh hope hopefully this one lasts. And we’ve got the Mazuno 8 iron, which is what the copper 8 iron was molded after. And we’ll see how they compare. Nice. Almost missed it. Nice. No, it didn’t break. It broke. Broke. It broke. It broke. Oh, no. Yeah, it uh it broke. It uh done broke right on the shaft. Who would have seen that coming? If you get it in the light, you can see he hit it. He towed it pretty good. And uh actually bent bent the club face. Looking like just pennies aren’t going to be strong enough. It was now clear that we were going to have to make some major adjustments to this thing if we wanted to make an actual playable golf iron. So, we started by increasing the size of the hoszle by melting on some wax strips and then carving the hoszle to reshape it. Per packard’s chpt conversation, it told him exactly how much wax or how much addition you needed you need to add to the hoszle. A 302 around the hoszle. So, the hoszle’s a little bit thicker. And then lead tape on the back with lead tape on the back. Once this is a copper club, 20 g instead of 40 and it’ll balance better and it’ll be as good as the Mazuno, at least better. Perfect. Got the furnace fired up with the new batch of pennies. And we also added a little bit of aluminum to the molten pennies, which should increase the strength of the metal by a significant amount. We ended up doing a ton of research on various alloys, and this seemed like the best way to boost strength without switching to a completely different metal altogether. You may have also noticed that we’re using a different kil here, which is because our cheap small kil broke and we had to find something to replace it with. And that big and ugly industrial kil was the most affordable option anywhere near us. So, we pulled the trigger on it. This casting actually came out super good. It’s just the hoszle didn’t fill in completely, which is a bummer because this thing looks awesome. That little bit of aluminum really makes this thing gold. It’s back to the drawing board yet again. For this mold, the main focus was redesigning the metal flow. We did that by increasing the size of the sprew and vents. We also used a much larger flask, which let us orient the mold differently. In with the last failed attempt and a bunch more pennies. Since this design has a much larger sprew and vents, we needed to melt down quite a bit more metal to make sure we could fill it all the way. You might even be able to just like uh carve the the rest of the toe a bit to blend it. Yeah. to make it look it just be like a slightly different design. This one came out good enough. It has some shrinkage on the toe, but Packard was able to blend it on the grinder, which does alter the shape slightly, but it still ended up looking pretty clean. We are back out on the range. We’ve got the new uh Penny 8 iron. And this one has some aluminum added to it, which I believe makes it uh Nordic Nordic gold, which uh obviously is golden color. And hopefully this makes it strong enough to where it’s not going to break on the first swing like the last one. Yeah, we’ll see if this lasts the range session. And if it does, we’ll take it out on the course and we’ll give it a proper course test and uh see how it performs. To test our metrics, we are going to use this Rapsoto launch monitor. We can’t afford a uh Trackman, but this was in the budget, so we’ll have this behind us to see how they compare to the Mazuno. Since our penny iron is molded after the Mazuno MP68, we started out by hitting that first and logging our metrics for it. Mainly looking at carry, launch angle, and ball speed right now. Uh let’s do Let’s do our iron. All right, game on. It’s a weird switch cuz it’s so light. Yeah, this might be it. It’s like a 50 g lighter. I mean, it looks good. Yeah. 155 carry fully survived. Okay, it’s a good start. Hey, Owen sounded nice. 160. What’s the swing speed on it? Uh 85. What was your swing speed with the Mazuno? I think it was like 84. Okay. I mean, so far it’s better. Oh, first bad shot. Blade ball. 171. You just delofted it. When you make something this hot, that’s just you got to be careful. It’s definitely tricky to go this light. We’re going to do more thorough testing later in this video, but for now, Packard was actually carrying the penny iron about 7 yards further on average than the Mazuno, which was a little surprising. That’s a good one to end on. Oh man, it is so light. Yeah, that one felt pretty good. 165 carry. Yeah, there’s just a sweet spot in there. Oh, that’s not it. Just like Packard, I was also carrying the penny iron slightly further on average than the Mizuno. There’s a lot more data for us to test, but this is a promising start to say the least. Damn, you could hit that thing high. It last. And uh I guess we’ll take it out on the course. Yeah. See how it does. Yeah. You got to show it off. Par 3 165. Think that’s up on the green. Little short. Yeah, so far it’s held up in one piece, which is really good. Um, it’s definitely hard. It’s hard to hit pier, but when you do catch it, it does feel like it kind of launches. I’d say probably more than my Mazuno. I think I’m hitting this further, which is crazy to say considering it’s a homemade club. But the swing speed’s faster. The club head doesn’t weigh as much. I’d be interested to see how it compares to the Mazuno if we add lead tape to this uh and match the club head weight. But so far it’s held up in one piece. When we do hit it good, it hits really well. Yeah, no complaints. For what it’s worth, I used to be about a 5ish handicap and Packard was a collegiate golfer around a scratch handicap, but both of us haven’t played much golf in the past 10 plus years, so it’s tough to say where we currently stand. This is by far the most golf we’ve played in years just testing these clubs for this video. And at this point, we were pretty impressed with how this club was performing. But we weren’t satisfied with the amount of data we had on it. So, we spent the next week hitting balls on the range, on the course, behind the shop, anywhere we could set up the launch monitor and hit a golf ball so that we could compile more data and get a true feeling for how this thing performed. We each ended up hitting over a 100 shots with both clubs. And these are the numbers that we got. These are Packard’s stat comparisons for the Mazuno versus the Penny Iron. He ended up carrying the Penny Iron six yards further on average than the Mazuno. His swing speed was a tad bit faster using the Penny Iron, which makes sense considering it’s a lighter club. Ball speed was 1 mph faster. Launch angle was slightly lower on the Penny Iron, but still really close. The shot apex was also nearly identical between the two. Spin rate was down 220 RPMs, which could be due to a number of different factors. and his smash factor was overall better with the penny iron, which is a measurement of how well he transferred energy with the club. It’s basically an efficiency measurement. My swing data with the club comparison pretty much mirrored Packard’s. My swing speed in general is slower than his, but all of our data is aligned except that I ended up hitting the Mazuno better than the Penny Iron according to the smash factor rating. So, with all this data collected, it seems as if our Penny Iron is actually outperforming the Mazuno, which was quite shocking to us. But that data doesn’t necessarily tell the full story. So we dug further into the numbers and looked at our shot dispersion using our launch direction and side carry data, which will basically tell us how accurate we were with each club. This is package shot dispersion with the Mazuno, and we can see a relatively tight spread. Now with the Penny Iron, it’s not bad, but definitely has a wider spread. The misses missed further than they did with the Mizuno. And we were curious if we add lead tape to the Penny Iron to match the weight of the Mizuno, would it perform even better? and would it tighten the dispersion? We’re not club fitting experts and since we had to add a lot of lead tape, we didn’t have much choice in placement. The main goal was simply to match the head weight. With the penny iron weighted, Packard’s dispersion definitely tightened up, which was really interesting to see. And it’s obvious when we compare it to the previous data of the unweighted penny iron. The dispersion now matched pretty close to the Mazuno overall. It’s also really fascinating that Packard’s metrics with the weighted penny iron were almost identical to the Mazuno, except that the spin rate was down 344 RPMs, which like I said could be due to a number of factors potentially because of the metal that we used. He was hitting the weighted penny iron really, really well with a smash factor over 1.3, which is insanely good. And look, we’re not claiming that we made an 8 iron better than the Mazuno MP68. Even with all the testing we did, there’s a lot more that goes into club performance. And to be fair, we essentially used the MP68 as our mold. That said, this was a really fun and interesting experiment, and we’re stoked with how the Penny Iron turned out. If we designed our own from scratch with a thicker muscle back and a slightly larger head, I think we’d have something pretty legit. We’ve got a bunch of ideas for unique club designs and weird builds, and this video was really just a test to see if there’s an appetite for this type of content. There’s not much like this on YouTube, so we’re figuring it out as we go. But we had a blast making this one. And if you want to see what we build next, consider subscribing. Thanks for watching.

We melted a bunch of pennies and turned them into a fully functional 8-iron — then tested it against a Mizuno MP-68 8-iron.

We took it to the range with a launch monitor and out on the course to find out.

This is one of the first golf clubs we’ve ever made… but somehow, it might actually work.

Watch to see how it performs in real-world testing — and whether copper pennies can hang with a tour-quality golf iron.

4 Comments

Very cool! Didn't know you could collect so much data and the comparison is very interesting

are golf irons typically a uniform density of a single material?

After seeing the gold, I’m surprised that no major club manufacturers sell gold clubs as an option. Looks very cool!

I really like this video, great content.