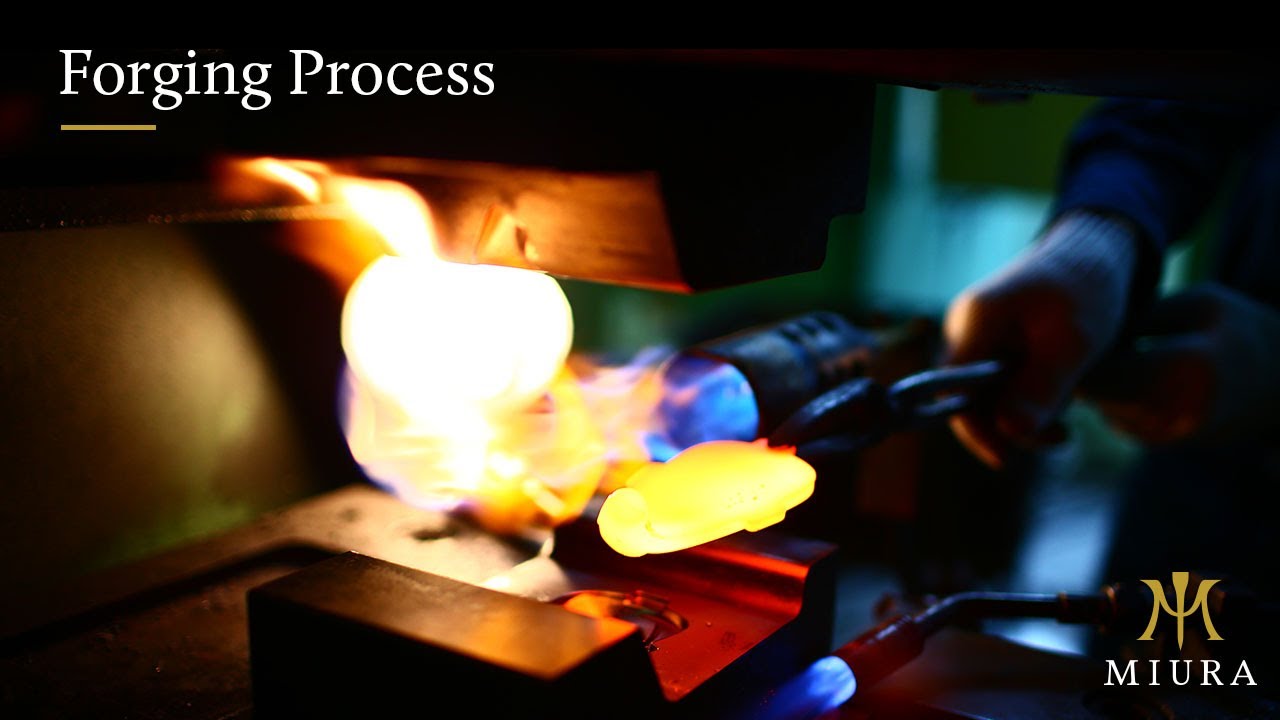

In the pursuit to create the perfect iron, Katsuhiro Miura recognized that the manufacturing process of forging irons was fundamentally flawed. So, he changed it. This resulted in a revolutionary new technique that elevated Miura irons to the highest industry standards with the tightest tolerances.

Miura-san’s patience and unique forging process ensures the grain of the steel is fine and uniformed, leading to a feel unlike anything else. The Miura feel. Every club is hand-crafted, one-by-one, and touched by Miura-San or one of his two sons, Shinei and Yoshitaka.

============= TIMESTAMPS =============

00:00 ➡️ The Raw Material

Miura uses raw material called S20C, which is also referred to as premium soft carbon steel. This premium steel is delivered to the Miura factory in various girths and lengths from which billets of steel are measured and cut to correspond with the desired weight of the individual models.

00:14 ➡️ First Forging

Once prepared to the desired length and thickness, the billets are heated to 1200°C. The first strike compresses the billet into a flat shape which allows the raw material to be placed easily into a die. The proprietary Miura process forges the club head without a hosel attached. This technique allows the Miura craftsmen to manipulate the grain structure and create the renowned Miura look and feel.

00:18 ➡️ Second Forging

Within seconds of the first strike, the heated steel is placed into a second die where the subsequent strike forges the steel into the golf head.

00:24 ➡️ Deburring

The innovation of the deburring technique is what separates Miura from its competition. Following the second strike, the club head is placed in a tray where it cools before beginning its journey to the next stage. Heating the club head once while delivering the first two strikes significantly improves the precision of the forging process.

00:37 ➡️ Third Forging

During this stage, the club head is reheated to a temperature of 800-900°C and receives its third strike. By allowing it to cool and then be reheated, the shape of the head is maintained while still allowing the grain structure to be manipulated. This is an additional and time-consuming step and requires the skill, patience, and experience of a Miura craftsman.

00:44 ➡️ Stamping of Groves and Badges

Stamping an iron includes marking the Miura logo, numbers, and scoring lines. A variety of proprietary machines and techniques are used to perform the steps without compromising the club head’s integrity. The most critical part of this process is the stamping of grooves and scoring lines. set the foundations for the lie, loft, and offset of each iron. If the scoring lines are imperfect, they affect the club head’s integrity.

00:53 ➡️ Hosel Friction Welding

01:08 ➡️ Outline Grinding

01:14 ➡️ Precision Hand Grinding

01:36 ➡️ Dynamic Barrel Polishing

01:43 ➡️ Hand Polishing

02:00 ➡️ Painting Filling

==============================================

MIURA Golf Clubs are NOW Available at GolfBox:

➡️

✴️ Become a free Subscriber, click the link below

Twitter ➡

Facebook ➡

Website ➡